Common Sewing Machine Issues

The most common issues people experience are the result of either the needle, thread or tension. Once you understand a few simple things, you’ll be confident in using your machine.

The issues: The machine wont sew, the thread breaks, the thread is bunching, the machine wont make stitches, the stitches are loose, etc.

Troubleshoot in this order:

Make sure the needle is new

1. Even a small burr, bend, etc on a needle can break threads. Change the needle after every big project.

2. Also make sure that the needle size you are using is correct for the fabric weight and thread type that you are using.

Needle inserted wrong

Make sure needle is inserted properly.

Thread & Needle Size Compatibility

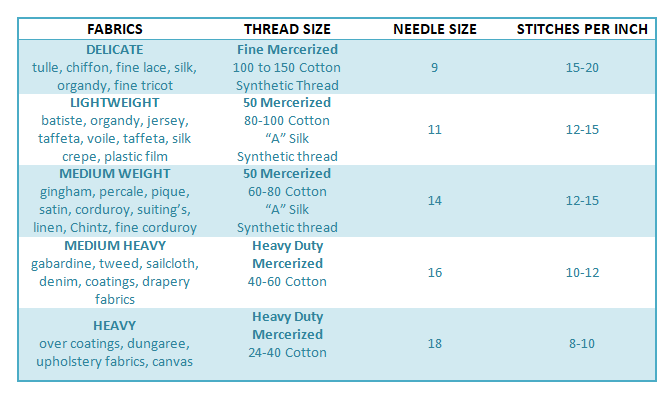

To ensure trouble free sewing, be sure that you're using the correct needle size and thread weight for the fabric type that you are using. Also be sure that the 'stitches per inch' is set to the correct setting. Refer to the needle and thread chart:

Correct threading of machine

Make sure the threading of machine is correct. One move in the wrong direction can prevent your machine from sewing stitches.

Needle threading

Make sure thread is inserted through the eye of the needle in the right direction.

Bobbin threading

Make sure that the thread in the bobbin is facing the correct way & threaded correctly, if not, you will not be able to make stitches.

Bobbin case

Make sure the bobbin is inserted into the bobbin case the right way and threaded correctly.

Bottom stitches are loose & ‘loopy’

If the bottom stitches are loopy, this means that the upper thread tension is too loose and an adjustment is needed. Increase the tension on the upper thread tension assembly in small increments. Turn left to decrease the tension & right to increase it.

Skipped stitches

1. The needle could be bent or installed incorrectly. Even if the needle is brand new, try another needle.

2. The thread/needle/fabric combination you are using are not compatible. First change your thread. Always make sure that the upper thread and bobbin thread are the same.

Thread is nesting/bunching up in the bobbin case

1. Make sure that both the machine and bobbin case are threaded correctly.

2. Check the needle that it’s installed right.

3. Change your thread.

4. Check the bobbin case area for stuck threads.

5. Adjust your tensions.

6. make sure that the needle size is compatible with the thread weight you are using.

Noisy machine

A loud/noisy machine usually just needs to be oiled. An oiled machine will run smoothly.

Always service your machine annually, even if it sits in storage because oil can gum up in the machine.

Machine runs slow

1. Make sure that the belt is not too tight.

2. Your motor might need replacing. Motors are available on eBay.

Always test sew on scrap fabric to test your stitches & make any adjustments needed – before starting a new project.

Note: Shops that are willing to service a vintage sewing machine are few and far between. Customers are driving considerable distances to bring their machines to me.

If you can't find a service shop you can easily service it yourself. It is easy, I promise. I even wrote several books about vintage sewing machines so that everyone can work on their own machines. Check out the books I wrote especially for servicing vintage sewing machines. The books are filled with pictures and easy to follow step by step directions.

If you have questions I'm happy to answer them M-F, 9-5, weekends if available, and holidays excluded. Contact me.

Connie